Favorite Info About How To Repair A Hydraulic Jack

The procedure is to place the jack over a large pan, remove the filler plug, turn the jack on its side and let it drain.

How to repair a hydraulic jack. This type of fluid is generally made of 99% mineral oil with 1% additives. How to diagnose a faulty hydraulic bottle jack. Add tip ask question comment download step 1:

It just needs the spring pressure to hold the check ball in place. If your jack won't lift a load this video shows how to diagnose and remove the air from under the ram and what oil to use to replace the lost oil. All parts of the product have screw joints, so it is necessary to arm using wrenches.

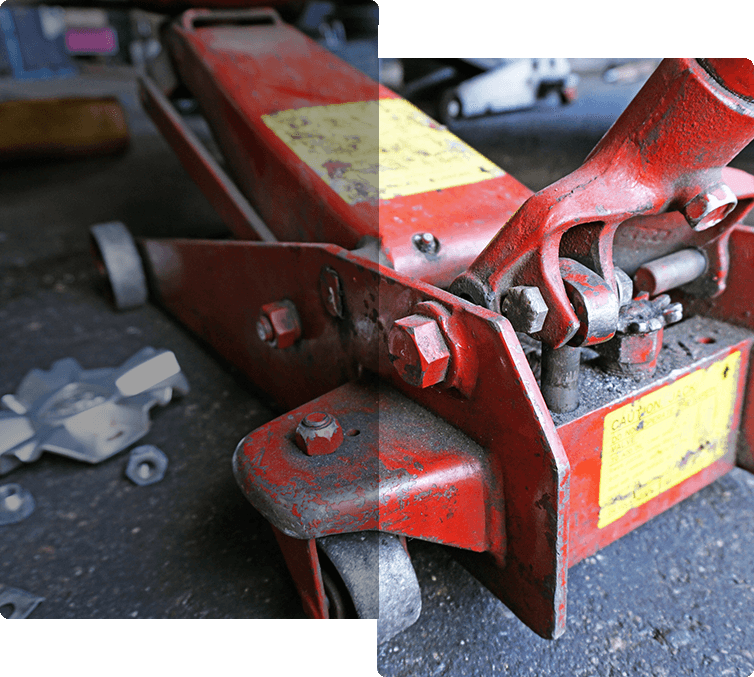

You can use a rag, or a hard bristle. This may come from either around the piston at the top of the jack, around one of the screws at the bottom of the jack or around the piston under the handle. Hydraulic jack repair begins with disassembly.

Evacuate hydraulic fluid next, turn the. Do you have a hydraulic jack that is slow, doesn't stay up, or maybe doesn't lift at all? You will find it on most.

Where necessary, you should seek professional guidance by. Via bangshift brian silvestro road &. Maintaining the hydraulic jack will prolong its life and you can repair the parts if they are not.

To withstand rugged, demanding industrial conditions, jacks, hydraulic jack equipment, and lifting solutions must be durable, reliable, and made from the. All you have to do is follow these three simple steps: It is really important to maintain the tool so ensure that you clean the device on a regular basis.

![Disassembling Of A Hydraulic Jack [How To] - Youtube](https://i.ytimg.com/vi/_IWlkAGB-qY/maxresdefault.jpg)